At Lebanon, Pennsylvania-based APR Supply Co., the action is nonstop whether it’s serving the customers or behind the scenes at company headquarters.

Every day gets started at APR with a “morning check-in” meeting. Key employees gather around President and CEO Scott Weaver’s conference table to let each other know what their day looks like.

The dizzying to-do lists are standard-operating procedure at APR, where the next great idea is right around the corner — always with the end game of best serving its plumbing, HVAC and hydronics customers throughout the four-state area of Pennsylvania, Delaware, New York and New Jersey.

“We don’t just sell boxes,” says Jeff Thompson, vice president of dealer products at APR and a three-decade veteran of the company. “The commitment we always have is for long-term relationships with our customers. We have been through thick and thin with our customers. We have their backs.”

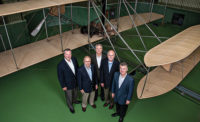

Front and center leading the charge is Weaver, a former ASA president, who fosters a high-performing culture at APR centered on analytics, innovation and by preparing his workforce to win business and help its customers succeed long-term. Under Weaver’s leadership, APR Supply has expanded to 37 locations that includes a unique joint-venture program with three other region distributors.

“Driven is the word I would use,” Executive Vice President and COO David Robinson says in describing Weaver. “He’s a change agent. The status-quo is uncomfortable for him. Scott has a drive for growth and excellence. He never takes a moment off. I’m thinking three years out and Scott is thinking five years.”

For its continued excellence and commitment to innovation, APR, a member of the AD buying group, is the 2018 Supply House Times Supply House of the Year.

Nonstop innovation

Multiple novels could be penned regarding the nonstop innovation and idea generation that occurs at APR. Here are some of the recent key highlights.

That corporate headquarters in Lebanon also houses APR’s distribution center. What once was a pasta-manufacturing plant now is the epicenter of almost everything APR. The DC recently was renovated, adding 10 additional dock doors, almost doubling capacity. In addition to new dock doors, the Lebanon DC also recently was reconfigured for better efficiencies for picking and shipping. Distribution Center Manager Dustin Hollinger notes order accuracy is at 99.48% up from 98.5% when the company first started tracking the metric.

Weaver with APR Supply Distribution Center Manager Dustin Hollinger. APR Supply recently renovated its DC, adding 10 dock doors, which almost doubled capacity. Photos by Mike Miazga and courtesy of APR Supply Co.

Weaver with APR Supply Distribution Center Manager Dustin Hollinger. APR Supply recently renovated its DC, adding 10 dock doors, which almost doubled capacity. Photos by Mike Miazga and courtesy of APR Supply Co.

“Back in 2003 when we moved here, we thought this was crazy,” Weaver says. “We did it anyway and now nearing capacity, we’re still innovating here. This building is part of the operational excellence piece that allows us to spend more time with our customers.”

APR utilizes 40 trucks a day. With that many trucks on the road, Weaver began researching ways to innovate on the maintenance end, which is why a truck-repair bay was added to the property where a mechanic now works in-house on the company’s fleet.

“You’re talking about a six-figure savings and now we are increasing the reliability of the trucks on the road,” Weaver explains.

Thinking outside the box, Weaver last year bought CAS Products, which distributes automotive detailing products to car dealerships. This unique venture utilizes the same distribution footprint as APR.

“I owned Weaver’s Wash and Wax when I was 13,” he says. “I bought my own products and charged 30 bucks a car and then taught the neighborhood kids how to wash and wax for four bucks. It’s the way I’ve always been. What other business models can we have where we can use the APR back-office expertise?”

APR also purchased a majority share in Environmental Recovery Solutions, a mobile refrigerant reclamation company, last December.

Process Improvement Manager Angie Starner (shown with Weaver) is the gatekeeper to a plethora of APR-related analytics data that plays a big part in the the company’s five core values: Customer, excellence, integrity, respect and results. Photos by Mike Miazga and courtesy of APR Supply Co.

Process Improvement Manager Angie Starner (shown with Weaver) is the gatekeeper to a plethora of APR-related analytics data that plays a big part in the the company’s five core values: Customer, excellence, integrity, respect and results. Photos by Mike Miazga and courtesy of APR Supply Co.

And a point of pride is the company’s aforementioned longstanding joint ventures with distributors Schaedler Yesco, Industrial Piping Systems and Rumsey Electric. Twelve locations combine APR and Schaedler under one roof, while five locations feature APR, Schaedler and IPS in the same branch, and Rumsey and APR are under the same roof in three New Jersey and Pennsylvania locations. All together APR has 15 joint ventures covering 18 locations.

“These joint ventures are successful because we have synergies with our partners. There is the investment with less risk because of that,” Robinson says. “We have similar cultures. We’ve never had any contracts with this so there is an incredibly high level of trust.”

Future growth is on the to-do list going forward. “If you are not growing, you are dying,” Robinson says. “We explore all opportunities for growth.”

More back-office magic

Analytics fuel many, many decisions made at APR. Process Improvement Manager Angie Starner calls up a plethora of data on a large projector screen in Weaver’s office, anything from financial statements to human-resource numbers. If there is a statistic to track APR-related activities, Starner has it at her fingertips.

“We automated a bunch of financial statements and it cut 20 hours out of the job right there,” she says. “We’ve cut out at least 60 hours from accumulating data. Not only are we more efficient, but we’re eliminating human error.”

On the IT side, things are firing into overdrive as well. Vice President of Information & Technology Christopher Bohn is leading a complete transformation of APR’s digital footprint, a project called Web 3.0 that went live in mid-August, around the same time the distributor’s highly successful dealer show took place in Hershey, Pennsylvania (attended by 1,450 people and 165 vendors).

APR Supply greatly reduced its truck-maintenance bill by building a maintenance garage at its distribution center and hiring a mechanic to work on the distributor’s fleet. Photos by Mike Miazga and courtesy of APR Supply Co.

APR Supply greatly reduced its truck-maintenance bill by building a maintenance garage at its distribution center and hiring a mechanic to work on the distributor’s fleet. Photos by Mike Miazga and courtesy of APR Supply Co.

“This is a big project for us,” Bohn says. “It’s our third generation of web commerce. We have replaced our entire web presence with this new system (Unilog is the provider). We’re starting from ground-zero building it up from scratch from the website to the e-commerce platform and all the content that goes in it. It’s been a huge undertaking getting it buttoned-up and presentable for our customers. It’s what we call hyper-customer-focused.

“The idea behind it is understanding why customers come to your website. They want to buy. We have a search function that is front and center. We know you want to buy stuff. We also have a function where if you pull up something, a list of related items also will pop up. You can look at all the other things related to that product.”

APR also is in the midst of further integrating the Office 365 platform into its daily operations. “I hope my legacy at APR becomes Office 365,” Bohn says with a laugh. “This tool will revolutionize things here. Everything will be in one spot for us. I envision our entire culture codified inside Office 365.”

It all comes back to people

Weaver is asked what the secret sauce is that has driven APR to the heights it has reached in recent times. “Everybody has product in boxes. We have our people,” he says.

When it comes to its employees, all 330 of them, APR is fanatical about education. “There are two sides to our education,” Thompson says. “There is the customer-facing part and the APR-employee-facing part so we can continue to grow our talent and help them be more efficient in their jobs.”

In addition to a robust customer-training program that features visits to the jobsite for education if necessary, APR has a bevy of programs in place to support and develop its employees. The Professional Improvement Program helps APR team members stay up to speed on the latest innovations and technologies that help them do their jobs better and more efficiently. APR also utilizes training courses from ASA, AD and HARDI.

“When we onboard employees, depending on their career path, we have a list of mandatory trainings they must go through,” Thompson says. “Their growth at APR Supply is in their hands.”

Weaver with APR Supply Distribution Center Manager Dustin Hollinger. APR Supply recently renovated its DC, adding 10 dock doors, which almost doubled capacity. Photos by Mike Miazga and courtesy of APR Supply Co.

Weaver with APR Supply Distribution Center Manager Dustin Hollinger. APR Supply recently renovated its DC, adding 10 dock doors, which almost doubled capacity. Photos by Mike Miazga and courtesy of APR Supply Co.

APR, in its third generation of family ownership, is in its 10th year of having a manager-training program that has produced a good amount of branch managers, while its member-run young leaders group comes complete with a board of directors and separate budget.

“Education is exceptionally important here,” Weaver says. “It’s made a difference in how we perform for our customers, which makes them sticky and want to come back because we provide that expertise. When we lay our culture on top of the education piece, it becomes very powerful.”

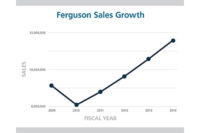

Weaver notes the company has grown 2,700% during his 28 years at APR. But that doesn’t mean Weaver and APR is done by a longshot. “I’m very happy with where APR is right now but I am far from satisfied,” he says.

And that’s even better news for APR customers.