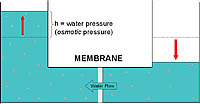

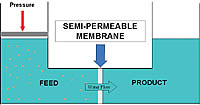

To understand reverse osmosis (called “RO” for short), it first helps to understand the natural phenomenon of osmosis. Simply put, osmosis is the flow or diffusion of a fluid - generally water - through a semi-permeable membrane.

Nature will often use osmosis as a way to equalize the concentration of two fluids having differing concentrations of dissolved substances. Semi-permeable membranes are all around us. The thin white lining inside a peeled hard-boiled egg, plant root cells, cell walls, all have the ability to transmit certain substances while excluding others.

For our purposes, Figure 1 shows two reservoirs that are separated by a semi-permeable membrane. Let's assume that the two reservoirs have different salt concentrations when introduced into these chambers. If left for a long enough time, nature will try to equalize the two chambers. Dilution of the more concentrated side will take place by movement of water through the semi-permeable membrane, until the chambers have equal salt concentrations as shown in Figure 2.

If you were to dissect a spiral-wound membrane, it would appear to consist of leaves of paper wrapped around a central collection tube. Looking more closely, you might notice a shiny film or gloss on the paper. It is actually this film that is the membrane material. This membrane layer may only be 0.2 microns thick while the paper acts as a support structure.

Water passes through the membrane, a mesh spacer between membrane sheets and eventually exits the center collection tube. Water that does not pass through the membrane exits the other end of the roll bundle (Figure 4).

How RO Works: Any time one talks about “filtration,” it is common to think of a filter as having pores of a certain size that allow only smaller-sized particles to pass through. This is not the case with RO membranes. RO actually removes dissolved ions from water. Ions are charged atoms, or groups of atoms, that originate from salts going into solution. Sodium chloride (table salt) produces the sodium ion and the chloride ion when it dissolves. Both can be removed by RO. Reverse osmosis literally is removing things that are the size of single atoms. It is not realistic to think of RO membranes as having pores.

While there are a number of ways to describe the function of RO membranes, a simplified version that accounts for how RO can remove these ions explains the phenomenon in terms of solubility. First, the membrane is assumed to behave like a dense liquid layer. Ions and water are thought of as being soluble in the membrane material, with pressure driving both through the membrane at their own unique rate. The diffusion rate of water molecules through the membrane material, however, is much higher than any of the ions in solution. Thus, while some ions do dissolve through the membrane over time, a much higher quantity of water molecules makes it through the membrane.

Operation: Even though it acts as a barrier to atom-sized particles in water, an RO is an inefficient sediment filter. Used as such, ROs would clog very quickly and stop producing water. Every RO membrane should be accompanied by proper pretreatment. In household applications, the pretreatment is typically built in. Pretreatment consists of sediment removal before the membrane, such as a string or fiber-type filter cartridge. Pretreatment also includes an activated carbon cartridge to protect the thin membrane polymer layer from substances that would oxidize it (such as chlorine in municipal water), thus breaching the membrane and allowing passage of untreated water. The water should also be free of high levels of precipitating ions such as iron or manganese.

There are two primary terms that describe RO operation:

- “Rejection” is simply the percentage of a substance that is excluded from the product water for a given feed water and conditions. Rejection is calculated by subtracting the product water concentration of a chosen ion from its initial feed concentration, divided by the initial feed concentration of that contaminant, and then multiplying by 100 to get a percentage. Typical rejections of contaminants by RO systems are above 95%, and even closer to 98% and 99%.

- “Recovery” is simply the percentage of water that is recovered as product. It is calculated by dividing the amount of product water passing the membrane by the feed water, and converting to a percentage. Typical recoveries for household applications are 20% to 25%.

Lastly, after purification, the product should be piped through plastic in household point-of-use applications or stainless steel for larger facility operations. RO water is so devoid of dissolved substances, it becomes aggressive towards piping metals that are easily dissolved, such as copper.

RO is a fantastic technology, but there are a few things that it does not do. RO membranes themselves will not remove small organic compounds such as trichloroethylene or trihalomethanes from water. However, the accompanying carbon filtration, if properly designed, might do so.

Also, it is possible that an RO user might assume that, since RO removes such tiny contaminants from water, it should also exclude microbes such as viruses and bacteria. This is not necessarily the case. A simple imperfection in a seal, or a microscopic tear in the membrane, would still yield, chemically, a high-purity water, yet allow a fraction of organisms to pass to the product side. Unless a manufacturer specifically states and validates through proper testing that a particular RO system can be used on microbiologically unsafe water, such systems should be applied to microbiologically safe waters only.

Standards: To find out more about a particular RO product, it is advisable to seek out a manufacturer's Performance Data Sheet detailing rejection percentages for a range of contaminants and the unit's expected daily water production while operating at a specified temperature and pressure. Making sure two membranes' daily production capacities are on the same footing will help ensure that you are comparing apples to apples.

An RO operated at a higher pressure will produce more permeate, as well as have a higher percentage of rejection of contaminants. An increase in temperature will do the same. Increases in dissolved solids, suspended solids, or percentage recovery for a system will have the opposite effects.

Also, for residential RO products, look for some form of third party certification to NSF/ANSI Standard 58 and/or WQA S-300. Third-party certification checks material safety (ensuring that wetted parts do not leach chemicals into the water) and structural integrity of the device under simulated operating conditions. The certifying body also verifies capacity numbers and recovery ratings. WQA's Gold Seal Program is one such certification. <<