The American Society of Civil Engineers’ 2021 U.S. infrastructure report card graded the United States wastewater system a D+, and the nation’s drinking water system received a C-. Additionally, according to the CDC, more than 500,000 kids in the U.S. have elevated levels of lead in their blood.

According to ASCE, there are 2.2 million miles of underground pipes in the U.S. that deliver safe water to millions of people — the majority of which have exceeded their useful life.

These concerns, coupled with the ongoing shortage of skilled worker and interest in trades — meaning even when funding is available to address aging infrastructure, there is not enough labor to actually do the job — call for innovative actions from plumbing professionals in order to deliver safe, clean and efficient water to our communities.

Proactive action

Trey Northrup, leader of LIXIL Americas, points out there is a lot of work to be done nationwide, and education is key. “President Biden recently introduced the Americans Job Plan which includes funding for modernizing our aging water systems. That's a great start,” he says. “But we really need to focus on educating the end user. People are flushing all kinds of things; wipes and sanitation products, they’re dumping oils, grease and food down the drain that have been clogging the pipes and causing even more deterioration in our infrastructure. Plumbing contractors, distributors and manufacturers can help coach consumers to be more mindful of these things, which can make a difference in our infrastructure.”

Seth DePuy, chief strategy officer at First Supply, agrees, saying being proactive will help address these issues. “We need to be much more proactive dealing with these challenges head on as these systems are not getting better with age,” he says. “We do expect to see a considerable investment over the next few decades in both wastewater systems and technologies to bring safe drinking water to the end user in the Midwest. All distributors need to continue to look for products that will provide the best solution for long-term sustainability. What worked in the past might not be the best solution for the future, so it is incumbent upon us to keep an open mind and look for products and technologies that will drive us moving forward.”

Drinking from the tap

A 2018 study performed by Penn State’s Population Research Institute showed that 61.4 million Americans say they do not drink their tap water, and that number has likely increased since.

Again pointing to the importance of educated users, Northrup says consumers often blame faucets for lead in their water, but in many cases, the faucet is the only thing protecting people from the aging infrastructure below. “We've created filtration faucets that allow people to drink directly from the tap,” he says. “We think that's a great way to keep families safe; we don't talk enough about how precious a water is as a resource, so in terms of product innovation, it’s important to stay focused on addressing spiked demand with technology that provides safe water.”

DePuy says distributors can help by supporting new technologies. “We need to keep this topic at the forefront and support new technologies as they come to market. We also need to be discussing these challenges with our customer base and offering solutions that will provide enhanced safety benefits. The industry is quite aware of the task at hand, and we need to keep chipping away at this problem each and every day as this will be best way for us to see real progress.”

American Standard has created filtration faucets that allow people to drink directly from the tap without worry. Photo courtesy of American Standard.

Toilet technology

In addition to working toward completely lead-free drinking water, the industry is aware that flushing, drains and clogs are factors affecting our infrastructure.

Kevin McJoynt, director of product management, fixtures for Gerber Plumbing Fixtures, notes efficient toilet technology can help in a big way. “Toilet technology can really help with aging infrastructure in one major way — improved drain line carry,” he says. “As all water consuming appliances and fixtures become more efficient, there is much less water in a building’s waste water system.”

McJoynt adds that the amount of actual waste has not changed. “Older existing drain lines were designed based on a much larger volume of water in the system overall, so now, the risk of waste building up at certain points in these older drain lines has increased. Well-designed toilets maximize their drain line carry, in addition to meeting other performance and consumption requirements.”

As the industry addresses water safety, water efficiency remains top-of-mind as well.

“Engineering technology in both toilet and urinal design to reduce water usage down to roughly a pint of water have assisted in water conservation has assisted in mitigating our infrastructure challenges,” DePuy says. “One of the largest pushes since the onset of COVID-19 has been the brightened spotlight on Sensor technology, which assists in both hygiene and reduction of water usage. Our industry will continue to drive advanced technologies to bring safe water to the end user."

Working together for a solution

Manufacturers and distributors are working towards solutions daily, but the true solution to the country’s infrastructure issues involves funding, standards and legislation help.

“New construction projects are being designed with these water efficient appliances in mind, but it is extremely difficult and expensive — if not impossible in many situations — to replace a building’s drainage system,” McJoynt explains. “It’s possible to coat or line the inside of drain lines in some cases, which can reduce friction in the line and possibly actually improve the drain line carry by slightly reducing the inside pipe diameter. But with the aging supply lines in the U.S., the industry must continue advocating for legislation and funding to systematically replace water service lines to maintain the safest possible water.”

It’s clear the solution will take ongoing efforts and strong partnerships industry-wide.

“Product innovation is helping to address issues resulting from aging infrastructure, but the depth of these problems is something product innovation alone cannot solve,” Northrup says. “It's going to take a full effort from everyone, not just from the government, but also from the private sector and making sure that we're sharing the technologies available so we won't be facing this again in another 50 to 70 years.”

McJoynt adds that working with industry associations is important when fighting for infrastructure help.

“Water efficiency is indeed critical to our environment, but the plumbing infrastructure has very little more to provide,” he says. “Replacing the millions of miles of aging and dangerous lead service lines must be a priority for all states, cities and local communities. Gerber is working closely with other manufacturers and distributors through membership in the Plumbing Manufactures Institute and the American Supply Association to advocate for and support responsible legislation regarding plumbing efficiency and safety.”

As the plumbing industry works toward solutions and innovations in responses to aging infrastructure, other factors such as lack of skilled labor and supply chain disruption are at play.

DePuy says honest, open communication with customers is a must.

“Most likely, the current supply chain challenges will influence business as we head through the end of 2021 and into 2022,” he says. “As an industry, we need to ensure we are having honest and transparent communication of these challenges to our customer base. We also need to provide alternative technology-based solutions that could help offset some of the labor shortage we have been and will be faced with moving forward.”

Northrup points out that manufacturers have a continued focus on ease-of-install in response to the labor shortage.

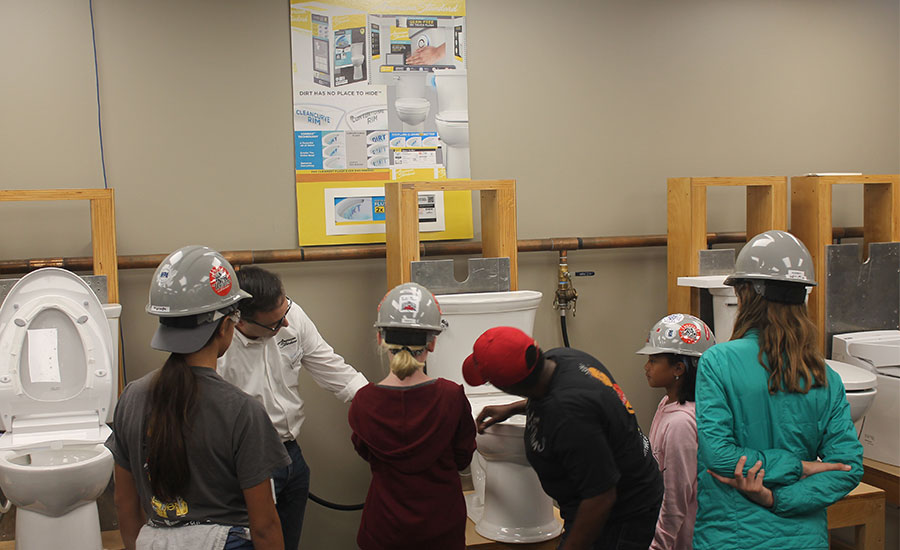

LIXIL recently hosted a camp in partnership with Tools & Tiaras as a part of it’s TradeUp initiative which fosters partnerships with customers, sales representatives and vocational technical schools to raise awareness of the industry, reach younger audiences and highlight the opportunities a career in the field offers.

“It’s imperative for ourselves and distribution partners to enable plumbers to be efficient in what they're doing,” he says. “We’re working to make sure technology to make installation of our products much easier than maybe they have been in the past because that will free up more of that valuable resource; a plumber's time.”

Ultimately, taking vigorous, continuous action is how the plumbing industry can work towards infrastructure solutions. “The largest concern is putting additional plans and appropriate resources into motion to work on the aging infrastructure challenge,” DePuy says. “It truly is time to stop talking about this problem and create action steps to drive solutions to improve upon this fragile part of our country. We are all aware of the challenge and that it is getting worse every day, now is the time to do something about it.”