Some manufacturers have already developed lead-free or low-lead plumbing products in response to California’s AB 1953, which specifies that pipe, fittings and fixtures used to convey drinking water will be limited to a weighted average lead content of 0.25% on wetted surfaces. Others expect to unveil their product response to the California legislation later this year or some time before Jan. 1, 2010, the compliance deadline.

“All of our members are independently looking at how they will comply,” said Barbara Higgens, executive director of the Plumbing Manufacturers Institute. “Now that the bill is law, manufacturers are committed to obeying it and though not easy, will design their products to meet the new requirements. We believe so strongly that the law must be obeyed that we have introduced our own legislation through Sen. Ron Calderon to require third-party certification to ensure compliance by all.”

At the time of this writing, the bill (SB 1334) had passed both houses in California and was awaiting Governor Schwarzenegger’s signature, according to Higgens.

Earlier this year Delta Faucet Co. introduced its patented DIAMOND Seal technology, an exclusive new water delivery system that eliminates contact with potential metal contaminants such as brass, copper or lead. The technology utilizes an integrated ceramic valve cartridge featuring one ceramic disc and one diamond-embedded ceramic disc and InnoFlex waterways made using a proprietary blend of PEX (cross-linked polyethylene) - a highly-engineered, very durable polymer material that is resistant to heat and freeze damage. Delta says its faucets with DIAMOND Seal technology will last 10 times longer than the industry standard and the PEX-C InnoFlex waterways are made to last at least 50 years.

In addition, Delta Faucet has conducted free 90-minute informational seminars for California plumbers, builders, wholesalers and code officials to explain CA AB 1953 and its new water delivery technology.

“DIAMOND Seal Technology … meets the requirements of AB 1953, which will help pave the way for water delivery of the future,” said Rick Roetken, vice president of marketing, Delta Faucet Co. “Its lead-free waterway system is an important step toward meeting today’s needs.”

While Delta’s solution is truly lead-free, with no lead contact, the other new technologies will have to do some field tests, said Russ Wheeler, president of Hansgrohe. He noted that other Masco companies are going to lead-free brass or low-lead brass (below 0.25%).

“Eco-brass is a no-lead brand,” Wheeler noted. “The one we at Hansgrohe are switching to can be called lead-free because it is below the maximum level. It is more expensive than regular brass and harder to machine. All products must be recertified. We will start doing a rolling change in 2009.”

Lars Christensen, product manager at Hansgrohe, pointed out that some of Hansgrohe’s faucet designs would not be compatible with Delta’s lead-free technology. For example, some of Hansgrohe’s kitchen mixer faucets feature minimalist styling with a faucet body that is too small to accommodate Delta’s technology, he noted.

Chicago Faucets learned from its own research and conversations with its commercial customers that they were looking for a cast brass product similar to what the company currently offers, according to John Fitzgerald, director of marketing.

“We will be introducing a line of faucets which we have named ECAST at the ASPE show in California in October,” he said in a September interview. “We will announce our solution in September via direct mail. In the latter part of September our sales reps will blitz the entire state of California.”

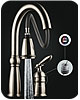

Delta Faucet Co.'s Victorian faucet features its patented DIAMOND Seal Technology.

“Our ECAST line has been certified by IAPMO,” Fitzgerald noted. “We are the first company to have our products certified by IAPMO. Beginning in September, you will see our product listed on the IAPMO Web site as meeting the AB 1953 standard.”

American Standard intends to comply with the legislation without introducing plastic materials for high-pressure waterway components, according to Dave Meisner, vice president and general manager, American Standard faucets.

“American Standard has used permanent metal molds brass technology for more than 30 years, so we’ve long been a leader in lower lead free brass casting technology manufacturing,” Meisner noted. “We’ve also been using ceramic disc technology since the 1970s. To comply with the new legislation to further reduce the small amounts of lead in faucets currently, we will modify the metal composition, thereby providing a product of superior quality and strength, not just replacing metal with plastic components.”

The applicable American Standard faucets will be converted to the new material process in early 2009, he added.

Sloan faucets meet or exceed all the requirements of NSF-61-Section 9, according to John Watson, director of technical services for Sloan Valve Co.

“Although Sloan faucets are exempt from current regulations, we’re committed to keeping up with low-lead requirements,” he said. “Blood lead levels in children and adults alike have dropped off substantially, and they continue to trend downward. In fact, lead levels are already well within the range recommended by the Centers for Disease Control and other government agencies. Much of this success comes from the efforts of plumbing product manufacturers that have taken appropriate steps to lower the lead levels in their products.”

T&S Brass plans to begin a rollout of its AB 1953-compliant faucets in the fourth quarter of 2008, according to Eva-Marie Fox, vice president of marketing. The products will be unveiled at the ASPE conference Oct. 25-29 in Long Beach, CA. The entire line of products designed to meet the needs of this new legislation will be introduced by the summer of 2009. Using the latest in technology and unleaded alloys, the company’s products will exceed the requirements of AB 1953, she said.

“We have developed a formula for lead-free brass and are working to implement it to meet the compliance deadline,” said Jeff Reilly, vice president of marketing at Symmons. Compliance efforts are complicated by the fact that the testing protocol has not yet been defined. A product may or may not comply with the mandated weighted average lead content of 0.25% on wetted surfaces depending on how the test is done, he said.

All Kohler faucets affected by the California legislation will be compliant by the deadline of Jan. 1, 2010, according to Brian Baratka, director of product marketing for global faucets. “Kohler Co. understands legislation is a serious matter and is proactively working with its customers regarding the product compliancy transition,” he said. “Kohler encourages all distributors and those in the industry to be mindful of the new legislation.”

A spokeswoman for Danze said the company will be “in full compliance” with state and national requirements.

An industry observer pointed out the irony that there may be hundreds of miles of lead pipe supply lines carrying drinking water in the state of California, but the legislators are focusing only on the last 12 inches of delivery - the faucet. Given that, the impact this legislation will have on the lead content in water may be insignificant, he said.

“When you look at the bigger picture, water is a finite resource,” said Chicago Faucets’ Fitzgerald. “The water shortages over the last year in Georgia, Florida and California have made water conservation a much more prominent issue. Conservation and sustainability have become equally important. The lead-free issue ties directly to sustainability.”

Chicago Faucets said its ECAST line, designed to comply with AB 1953, will be available in California in October 2008.

National Implications

“Eventually this legislation will probably set the standard for the national legislation pertaining to this issue,” said Fox of T&S Brass.Fitzgerald of Chicago Faucets projected a time frame of five to seven years for national legislation regarding lead-free to be enacted, noting that it has to be put in the proper vernacular.

“History has a tendency to repeat itself,” he said. “When California enacted Proposition 65, that led to a national lead standard. We expect the lower lead content requirement to be adopted throughout the United States.” He noted that Vermont, Michigan and Washington are among the states that are considering this type of legislation.

“We expect there to be a consumer preference and consensus for ‘lead-free’ products independent of national legislation,” said Meisner of American Standard. “We would expect the development of an amendment to the national Safe Drinking Water Act of 1986 mirroring the experience of the 1996 California Proposition 65 legislation.”

Regardless of whether or not national legislation is enacted, manufacturers are likely to apply the requirements to all affected products nationally, said Reilly of Symmons. “It’s very difficult to maintain two streams of raw materials going through the same machines,” he pointed out. “As a manufacturer we would prefer to have one version made for everyone, even if the no-lead/low lead is not required everywhere.”

PMI hopes this legislation does become national, provided a realistic compliance deadline is provided, Higgens said. “PMI is working toward the goal of enacting the California legislation nationally. Now that we have a template, we would like all states to adopt this protocol but with the enhancements of the PMI ‘clean up’ bill to require third-party certification to ensure universal compliance. In addition, our template legislation tightens up some of the vague language and definitions of the California bill. We are working to avoid a patchwork of conflicting product material requirements.”

Working Together

Initially there was a lot of push-back on AB 1953, observed Fitzgerald of Chicago Faucets. “As we get closer to January 1, 2010 we are hearing less push-back and more on possible solutions and how manufacturers can work toward providing products that meet the new standard.”American Standard developed the motto “Plumbers Protect the Health of the Nation” in the 1930s, Meisner said.

“We have been working in concert with plumbers, industry associations and legislators to ensure our products meet the strictest health, safety and environmental requirements,” he said.

PMI’s Higgens noted that the proponents of AB 1953 are listening to important input from manufacturers.

“PMI would like legislators to use the talent and knowledge within our industry to write better legislation right out of the gate,” she said. “There is a tendency to suspect and reject input from manufacturers and rush to enact legislation without proper consultation with those affected. PMI is earning a reputation for being a credible resource. We are reaching out to make PMI available to be consulted prior to the writing of legislation to avoid false starts, flawed legislation and unintended consequences. In other words, to achieve the classic win/win! That is the purpose ofwww.safeplumbing.com.

California AB 1953: Some Key Facts

Products affected by AB 1953 include all devices at the point-of-use that are intended to dispense water for human consumption, such as kitchen faucets, bar faucets, manual lavatory faucets, supply stops, bubblers, glass fillers and pot fillers.Products not affected by this legislation include electronic faucets, shower, laundry, service sink and laboratory fittings designed for purposes other than dispensing water for human consumption.

It does not distinguish between residential and commercial uses.

Products must receive certification from an independent ANSI-approved, third-party testing organization.

Information courtesy of Chicago Faucets.