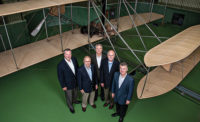

This group of Coburn’s senior management

features more than 300 years of experience with the company. Photos by Mike Miazga and courtesy of Coburn

Supply

Over the years, Beaumont, Texas-basedCoburn Supplyhas run advertisements on local radio station KLVI-AM News Talk 560.

Coburn’s Senior Vice President and General ManagerBill Geyserrecently heard longtime host Al Caldwell reading one of those ads on his morning show. Caldwell started to ad-lib and concluded the spot with, “Go over there and get Coburn-ized!”Coburn’s PresidentDon Maloneynotes the Coburn-ized phrase at one time was one of the company’s marketing slogans.

Coburn-ized is much more than just a catchy marketing slogan. It’s a fact of life for the 900-plus-employee company, whether in the way its employees are set up for success or the vast measures it routinely takes to make sure customers are satisfied to the highest degree.

Coburn’s long-term prosperity in the Gulf Coast region and its commitment to success in the future makes it an easy choice as the recipient of the Supply House Times’ 2012 Supply House of the Year honor.

“Coburn’s provides good service and quality products and has quality management,” saysKenny Granger, owner of Plumbing Specialties, a plumbing contractor in Beaumont. “They are very customer-oriented.”

Assistant Branch Manager Cliff

Allensworth (left) and Branch Manager Mike Smith run Coburn’s Beaumont store,

blocks from corporate HQ.

Customer service is king

Providing superior customer service is a way of life at Coburn’s and has been sinceAlbert Coburnstarted the company in 1934. Don Maloney, whose father,Arthur, and uncle,James, were key figures in the company’s development in earlier years, recalls seeing instances of above-and-beyond customer service dating back to his childhood. Don and his brother,A.J. Maloney(Coburn’s executive vice president), are Albert Coburn’s great nephews.“We used to hold shrimp boils,” Don Maloney says. “There would be bands playing and street dances. Back then, there wasn’t a lot of wealth. This was a venue where customers could bring their wives and go have a good time and eat and drink. It was a big thing back then.”

Don Maloney, who now leads the company with A.J., remembers the days when contractors had keys to Coburn’s showrooms so they could take customers there after hours. He also recalls a time in the 1950s and ‘60s when the company financed customer remodel jobs.

“We understand how to service customers,” Geyser says. “It’s become a very good marriage. We know what they need from us and we know what they need in order to succeed.”

Darren Tramel, Coburn’s vice president, general manager out of Longview, Texas, adds: “The No. 1 reason we are successful is we never forget the main reason for our success - our customers. We value customers and we never forget why we are in business and why we get up every day.”

Granger cites a recent instance where a hospital shut down its surgery wing because a part on a boiler went bad. One call to Coburn’s Assistant Branch ManagerCliff Allensworthat Coburn’s original store in Beaumont took care of the problem in short order.

“There were three of these high-pressure steam regulators in the country,” Granger explains. “Coburn’s flew one up from North Carolina. That was a big deal for us. We were able to get that part of the hospital up and running the next day.”

(L-R): Elaine Jackson, Jan Best,

Stephanie Tritico and Tarin Cook Henley staff Coburn’s Beaumont showroom.

“They were dead in the water if they weren’t able to finish that job before the inspector arrived,” he says. “We took one of our delivery trucks up to Dallas on a Saturday morning and got them what they needed at no extra charge. It was a 2 ½-hour drive one way. We saved them a ton of money. They couldn’t believe we would do something like that. We always look at things from other people’s perspectives. Customer service sets us apart. Our claim to fame is what we do to make sure customers are profitable. Something like that means more than price. Price is important, but service is what makes you great.”

Stephanie Tritico, manager of Coburn’s showroom in Beaumont, says the majority of her store’s business comes from repeat customers. “Our willingness to help people sets us apart,” she says. “We had a lady come in here recently with a faucet from 10 years ago that needed to be repaired. We went the extra mile for her. Customers know they will be taken care of when they come in here.”

Jan Best, a sales consultant on Tritico’s staff, is starting to see double, so to speak. “In the 11 years I’ve been here, we’ve redone several customers’ bathrooms and kitchens,” she says. “Once people buy material from Coburn’s they become repeat customers. We have people that will call us back 10 years later. Customer service is our top priority.”

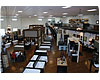

Coburn’s Baton Rouge showroom is one of

29 in the company.

Spreading the Coburn's word

Coburn’s, ranked No. 16 on the2012 Supply House Times Premier 125list (ranking based on 2011 sales), features 49 branches and 29 showrooms throughout Texas, Louisiana, Mississippi and Tennessee. The company operates three distribution centers and stocks two regional pipe yards. Mississippi and the Memphis, Tenn., areas are the company’s two most recent expansion projects, both occurring within the last five years.Expansion, though, is not something the company walks into blindly. “We’ve been a company that concentrates on sales and expenses,” notesTrey Berlin, one of Coburn’s directors and a senior vice president and general manager based out of Baton Rouge, La. “We’ve never stretched ourselves or taken on too much debt. We’ve survived recessions. When the housing boom hit 15 years ago, we were ready to expand.”

Don Maloney jokes about one old inner-office practice that demonstrates the company’s commitment to a sound bottom line. “We used to get hand-written, inner-office memos primarily from our dad and uncle on used envelopes,” he says. “We’ve always watched our pennies.”

Coburn’s makes sure expansion occurs only when it makes sense from geographic and staffing perspectives. Take for instance, its expansion into Mississippi.

“A.J. and I were visiting a vendor who told us we should expand into Mississippi because another distributor there was no longer involved with them. They said the whole state was open to us,” Don Maloney says.

The Maloneys pulled the trigger on expansion only because they felt experienced staffing would be available. “You have to investigate what type of personnel is in a particular area,” says A.J. Maloney, a school teacher before joining the family business. “You need good people to staff these locations. We knew there were quality people available to work for us in Mississippi so we said OK. This is still a people business and you need quality people able to take care of customers.”

Elkay Vice President-General Manager of Traditional PlumbingMark Whittingtonwatched Coburn expand even during uncertain economic times. “What impresses me most is their burning desire to expand and grow,” he says. “Don and A.J. did not entrench. Instead, they expanded their model to grow and prosper. They looked for ways to expand in their retracting markets and are winning because of it. It was a bold move by a highly respected company.”

Customer service is a major point of emphasis at

Coburn’s.

“We had a grand opening, and all the regional vice presidents and the Maloneys came to Memphis,” he recalls. “The Maloneys stood out there and cooked food and served it to customers. They told us this was our job to take care of our customers and let the company worry about supporting the branch. How many times do you see the owners of a company serving food and giving customers Cokes? You don’t. That’s the kind of company they are.”

Geyser adds expansion for the company doesn’t necessarily mean opening a physical store or showroom. “Expansion for us is often just expanding existing markets with new products,” he points out. “We’ve added electrical or HVAC in some of our locations and that takes new inventory and new people.”

Coburn’s, which is a member of the American Supply Association, Southern Wholesalers Association and HARDI, skews about 50% in plumbing and the remainder 50% in HVAC, electrical, water works and builder products. Coburn’s recently added appliances and cabinetry to its portfolio and is in the process of remodeling all its showrooms.

“We look at expansion internally and externally,” Don Maloney says. “Internally, we focus on trying to move all segments of business into every branch that can handle it. For instance, not every branch is well-versed in electrical. With external expansion, it depends on what is available and what fits the scheme. The underlying thing is people. You have to have quality and competent people in a marketplace in order to expand.”

Technology updates also have fueled the company’s growth in recent years. Don Maloney remembers a time when 60%-75% of the company’s sales were entered into an inventory management system at the end of each month. Upgrades in computer systems have made that a thing of the past.

“We’ve been very open to adapting technology,” A.J. Maloney says. “It’s been a big benefit and something that has helped us grow. We’re constantly looking at the structure of this organization and making sure we meet the conditions of the marketplace. We’ve gone to EDI (electronic data interchange) with our vendors and we’ve started using VMI (vendor-managed inventories) with key vendors. All these things take time and process out of everyday transactions. We’re able to get more information into the hands of people who need to make decisions with it.”

Coburn’s Vice President of Sales and MarketingJim Fullerreports the company will roll out a new website in spring of 2013. Coburn’s also has an active Facebook page and regularly works on Web search engine optimization techniques.

“We understand the Internet is part of the marketplace,” A.J. Maloney says. “We’ve put together a good program. We have the capabilities for customers to see information on products as well as access and pay invoices.”

Fuller adds: “We make sure we are staying in front of things such as social media and the Internet. We’re paying attention. These are additional ways we meet the needs of our customers.”

(L-R): Bill Geyser, Trey Berlin and

Danny St. Pierre with Don and A.J. Maloney. Berlin is celebrating 40 years with

Coburn’s.

Surrounded by quality people

Superior customer service goes as far as the employees providing it, and Coburn’s goes to great lengths to not only make sure it hires top-notch employees, but provides an environment where its workers can succeed to the highest degree possible.“It’s a family-run business, but we have all the perks of a big company,” saysMerlin Frederick, a 43-year veteran of the company and the branch manager of Coburn’s store in Lafayette, La. “I describe us as a big-small company. There is a mutual respect. They allow the managers a lot of privileges to make decisions on a lot of things.”

Frederick’s 43 years with the company isn’t an oddity. At company headquarters in downtown Beaumont, Don Maloney pulls out a list of 2012 company service awards that shows 120 employees cited for either 5, 10, 15, 20, 25, 30, 35 or 40 years of service. Berlin is in his 40th year with the company, while Tramel has been with the company 20 years. Vice President of Finance and AdministrationPam Mouton, A.J. Maloney’s daughter, is in her 15th year. Don Maloney’s sonsMichael(director of marketing) andPatrick(HVAC division manager) and daughterColeen Mowery(event coordinator) also work for the company, as does A.J.’s other daughterChristy Ferris(special administrative projects), marking the fourth generation of family to work in the company.

Coburn’s executive and general management team that gathered in Beaumont for an early October meeting boasts a combined 302 years of experience with the company. Coburn’s has six general managers responsible for branch operations in their regions and five division managers who provide support and expertise for each of Coburn’s five business units.

“Coburn’s is a great company to work for,” saysTarin Cook Henley, a nine-year company veteran who works at the Beaumont showroom. “It’s a family-oriented company. Management here allows family to come first. They are very flexible.”

Joyner adds: “This company works from the bottom up instead of the top down. Most companies have a corporate headquarters. Coburn’s doesn’t recognize any corporate headquarters. Coburn’s has a service office (the corporate building in Beaumont). They funnel everything back down to management and the employees. It’s a totally different atmosphere here, which makes servicing customers that much better. It’s a better fit for employees. Employees feel an ownership in the company. You don’t feel a thumb down on your head. You don’t hear, ‘You’re gonna do that.’ Instead, you hear, ‘What can we do to help you?’”

Coburn’s answers the “What can we do to help?” question by providing comprehensive training and solutions to problems for its employees. Mouton explains the company started a training system in 2005 designed to bring employees up to speed on company policies and philosophies.

“We needed to be able to communicate with our employees about what Coburn’s is about,” she says. “We have several different modules. We have a first five days orientation and our Coburn University provides position-specific training. We found it can be very frustrating having so much coming at you at once. This is a good approach that gets employees up to speed so they can do their jobs properly and help best serve our customers.”

Pictured, second from left, are: Baton

Rouge Branch Manager, Scotty Daniels; Vice President, General Manager, Jim

Dinser; Regional Manager, Larry O’Neal and Vice President, General Manager

Darren Tramel.

For those interested in moving into higher positions, career-advancement training comes via the company’s leadership and management system. “This ensures employees are prepared to take on new roles when they are ready for it,” Mouton says. “As we continue to grow we want to make sure we are giving our employees the best chances to advance and set them down the right path.”

Coburn’s also is aggressive in how it rewards its employees. The company offers a profit-sharing program that in many years has yielded 10% of an employee’s annual salary. Strong health-care and 401K plans are offered as well.

In reference to taking care of employees, Coburn’s Greater Houston Area General ManagerLarry O’Nealremembers having a closed-door meeting with Geyser months after starting with the company. To say the least, he was worried.

“Bill says Don and A.J. are very concerned about the rising prices with gas and they’re worried about how the employees here are getting to and from work,” he says. “They gave raises to help with gas prices. That was so refreshing to see. That proved to me everything I needed to know about the company.”

Allensworth simply likes the fact his voice is heard. “I feel more involved in the overall direction of the company,” he says. “We’ll go down the street to headquarters for meetings and talk right to the owners. They look for our input and then they react to it and put things in motion to help our business.”

Don (left) and A.J. Maloney are the

third generation of family ownership at Coburn’s.

Moving forward

The Maloneys, who helped found theEmbassy buying group, take pride in being a strong independent wholesaler in an age that has produced industry consolidation and uncertainty due to the recent economic struggles.“Being an independent is still vitally important,” Don Maloney says. “We’re not governed by Wall Street or private equity. It’s just us. These days, it’s a challenge being an independent, but it’s worth the challenge.”

The Maloneys represent the third generation of family ownership in the company. However, the brothers don’t feel the pressure of continuing on the family tradition.

“I was influenced by my dad, my uncle and my great uncle. They gave us some basic guidelines,” Don Maloney says. “One is if you take care of people, they will take care of you and if you are kind to people, they will be kind to you.”

A.J. Maloney adds: “This is more than a family business. The Coburn’s family is bigger than the Maloney family. We’re stewards of an ongoing enterprise. Our responsibility is to the people that work for this company and the customers we serve.”

Coburn’s Beaumont store receives two

trucks daily from the company’s distribution center.

Spreading the wealth: Three distribution centers provide maximum service levels for Coburn Supply customers

Coburn Supply is deeply rooted in providing extraordinary levels of customer service.One major contributor to that commitment is the Beaumont, Texas-based company’s three distribution centers and two pipe yards. Coburn’s has distribution centers in Jasper, Texas (opened in 1991), Eunice, La. (opened in 1989) and Pearl, Miss. (opened in 2009). Pipe yards operate in Jasper and Eunice.

“It took us awhile to build these infrastructure systems,” Coburn’s Executive Vice PresidentA.J. Maloneysays. “We now have 43 tractor trailers delivering out of the five facilities.”

Coburn’s Senior Vice President-General ManagerBill Geysernotes 65% of the company’s inventory funnels through the distribution centers and pipe yards.“A lot of competitors have to wait three days to get it from the factory,” he says. “We can get it there in the morning.”

Maloney adds: “We made a conscious decision to have what the customer wanted when he wanted it. Our objective is to outsell the competition by having products when people want them. When there is an order, we are going to fill it.”

Each Coburn’s branch receives a delivery truck every morning from one of the distribution centers. The Beaumont branch receives two trucks, soon to be three. “The truck is there at 8 a.m., every day,” notesJim Dinser, a Coburn’s vice president and general manager based out of Richland, Miss.

Merlin Frederick, branch manager of Coburn’s store in Lafayette, La., has seen a lot in his four decades on the job. The advent of the distribution center ranks right up there. “Having that truck here from the distribution center every day has been remarkable,” he says. “Customers know they can depend on us for having the products they need. It’s all about availability of product.”

That ability to have product in place when it’s needed allows Coburn’s branches to further establish themselves as the market leaders in customer service. “When I say customer service is king here, I mean it,” says Beaumont Branch Manager Mike Smith, who has been with the company for 30 years. “Everybody has the same breadth of product and has fairly close

Turning a negative into a positive

Teamwork helps Coburn Supply rebound from recent hurricanes.Doing business in the Gulf Coast region comes with one inherent risk.

Catastrophic weather events.

Coburn Supply branches and showrooms have seen more than their fair share of hurricanes in the last decade. Hurricanes Katrina and Rita affected Coburn’s locations in 2005, while Hurricane Gustav wreaked havoc on several stores throughout Louisiana. Twelve days after Gustav, Hurricane Ike made an appearance and destroyed the company’s Galveston, Texas plumbing office.

While those storms affected many lives throughout the Gulf Coast region, Coburn’s was able to take positives out of extremely serious situations.

For instance, after the destruction Katrina and Rita caused, the company created a redundant site in Longview, Texas along with a company-wide evacuation protocol that ensures Coburn’s stores will not be affected by future disasters and can continue business as usual. The company was slated to perform its annual test run at the Longview site in early November.

“The site has a system that has complete data backup of everything we have,” Coburn’s Executive Vice PresidentA.J. Maloneyexplains. “If we need to evacuate from Beaumont, we can send essential people to Longview and continue to operate the business from there.”

Maloney notes the company’s disaster evacuation plan was recently updated to include other catastrophic events such as fires and terror attacks, additions fueled by a recent discussion at an Embassy buying group meeting.

While technical logistics will help in the future, Coburn’s knows it can rely on the strength of its employees in the event more bad weather strikes any of its locations.

That was certainly the case with previous storms. Coburn’s PresidentDon Maloneyremembers getting a call from 42-year company veteranDanny St. Pierre(a Houma, La.-based vice president and general manager) shortly after Katrina struck.

“Danny called and was upset and wondered how we were going to pay all these people when the branch was shut down,” Don Maloney says. “I told Danny to let everybody know they would get paid a 40-hour week and we’d match commissions. People have to live. The main thing was to focus on getting that branch back up in the right direction. Just about everybody in the company pitched in without asking. People contributed clothes and money to help fellow employees. What our employees did for us in helping get things back up and running, we got it back tenfold. Business was phenomenal after the storm.”

One Coburn’s employee displaced by Katrina was having difficulty finding a home for her horses. A Coburn’s customer came to her aid and offered his pasture in Lafayette, La.

“She was very worried about where her horses were going to go,” Don Maloney says. “When the customer offered his pasture, she was OK. You have to understand what is important to people.”

With all the storms, Coburn’s was quickly able to get operations up and running in affected areas. After Hurricane Ike, Coburn’s was one of the first plumbing and air conditioning distributors to reopen on Galveston Island. Coburn’s had trucks into areas affected by Rita within 24-36 hours.

“The storms helped us come together even more so as a company,” Don Maloney says. “There is a common bond in adversity.”

Supply House of the Year Previous Winners

1959 - Robertson Supply1960 - Noland Co.

1961 - EMCO Ltd.

1962 - Raub Supply

1963 - Atlas Supply Co.

1964 - A. Y. McDonald

1965 - Horne-Wilson

1966 - Taylor Companies

1967 - Palmer Supply

1968 - J. Levitt

1969 - Kiefaber Co.

1970 - None

1971 - None

1972 - None

1973 - Hajoca

1974 - Ferguson Enterprises

1975 - Standard Plumbing Supply

1976 - CSC Inc.

1977 - Trumbull Supply

1978 - Harry Cooper Co.

1979 - F. W. Webb

1980 - Slakey Bros.

1981 - RAL Corp.

1982 - Familian NW

1983 - Moore Supply

1984 - Apex Supply

1985 - Noland Co.

1986 - Familian Corp.

1987 - Hughes Supply

1988 - Davis & Warshow

1989 - LaCrosse Plumbing Supply

1990 - A. Y. McDonald

1991 - RAL Corp.

1992 - Columbia Pipe & Supply

1993 - LCR Corp.

1994 - Ferguson Enterprises

1995 - Hughes Supply

1996 - Familian NW

1997 - F. W. Webb

1998 - Apex Supply

1999 - Torrington Supply

2000 - Wolff Bros.

2001 - Lehman Pipe & Supply

2002 - Todd Pipe & Supply

2003 - Davis & Warshow

2004 - WinWholesale

2005 - Castle Supply

2006 - Red Man Pipe & Supply

2007 - Standard Plumbing Supply

2008 - Wilson

2009 - Robertson Heating Supply

2010 - Rampart Supply

2011 - Modern Supply

2012 - Coburn Supply