The essence of plumbing is its mechanical genius. Unfortunately, its most clever innovations usually are not apparent to the casual observer, being hidden within the housing of a product or behind a building wall. People take for granted devices such as the T&P valve, kitchen disposal, flush toilet and so many of our industry's other useful gadgets that have made their lives safer, healthier, more comfortable and convenient. Even plumbers who work with these mechanisms every day tend to lose sight of the ingenuity that went into them.

By spotlighting these inventions of significance, we pay tribute to the innovators of the past and hope to instill a greater appreciation of the PHC trade heritage. We also hope to instill a better understanding of how certain products work. The breakthroughs featured here were all invented before 1975, each proving its ability to withstand the test of time.

In compiling this series we tapped the engineering departments and archives of major plumbing manufacturers for guidance. We thank them for their cooperation.

Innovations At Kohler Co.

1911: Kohler Co. introduced the industry's first one-piece recess bath with an integral apron. Before this time, built-in baths were cast in two separate sections - the tub proper and the apron. The apron and the tub were then either fitted together by the plumber when the tub was installed, or the two pieces were welded together at the factory before the fixture was enameled. The new one-piece tub, void of crevices, joins and seams, was more sanitary and attractive.

Moen's Single-Handle Mixing Faucet

Few people have been as synonymous with inventions and innovations as the late Al Moen. At one time he held more than 75 patents, but his most revolutionary was the one issued in 1942 for the single-handle mixing faucet.Moen's invention rose from necessity. While an engineering student at the University of Washington, Moen worked evenings in a garage to pay his tuition. One day he burned his hands while washing them under a conventional two-handle faucet. From that experience, he resolved to create a faucet that would give the user water at the desired temperature. After designing several faucets, he sold the first single-handle mixing faucet in San Francisco in late 1947. Today single-handle faucets are a popular choice in American homes.

Moen's innovative mind also produced the replaceable cartridge, a push-button diverter, back-to-back installation and the swivel sprays.

Cherne Industries' Test-Ball Plug

Some clever inventions are stunning in their simplicity. A great example is the pneumatic Test-Ball Plug developed in 1952 by Lloyd Cherne.He was on a job in northern Michigan when, much to his dismay, the cast iron mechanical plug he was using (the only plug available at that time) to conduct the stack test would not fit through the cleanout tee. So he purchased a rubber playground ball from a Woolworth store, vulcanized a stem on it and came up with a crude pneumatic test plug.

Returning to his home base in Minnesota weeks later, Lloyd began experimenting with his idea and within six months began making Test-Balls, bringing them to market in 1953.

The Cherne invention simplified the steps taken to test plumbing in a building and contributed to the now universally accepted practice of mandatory testing. The plumber now had a test plug that could be used in all common pipe I.D.s, that could conform to out-of-round pipe, that was guaranteed to handle common test pressures and, best of all, was much safer when used with an extension hose than cast iron mechanical plugs.

Spirotherm's Air Eliminator

The Spirovent was an outgrowth of an attempt to design highly efficient liquid heat exchangers. In 1972, Frans Roffelsen experimented with new types of heat exchangers using water-based test installations. He found no brand of air eliminator available that removed enough air to avoid distortion of the testing results.The cyclical growth and release of micro-bubbles, due to temperature changes, led to faulty test results. The theory behind this absorption process was described many years ago in Henry's Law, stating that the amount of gas absorbed by a liquid is defined by temperature and pressure.

A research project eventually led to the creation of the Spirovent air eliminator. The special Spirotube inside the Spirovent proved to be the essential part that separated all air, including micro-bubbles, originating in the heat source. This enabled water to absorb even trapped air at remote and inaccessible areas. In conjunction with a reliable air valve mechanism, without a cap to ensure uninterrupted working, it became a mature product ready for mass production.

Elkay Takes Pressure Off The Cooling Tank

Elkay Mfg. Co. made a major breakthrough in 1974 with the invention of its non-pressurized water cooling tank.Until then, most water cooler tanks were kept under pressure. Elkay engineers noted that with cold water under continual pressure within a cooler, a water leak or rupture could develop overnight or over a weekend, going undetected for many hours or days and causing extensive damage to the surroundings.

In the new design, the only water under pressure was the water from the source up to the valve and the regulator cartridge. When activated, the push button valve opened to allow water to flow into the cooling tank and then out the bubbler. In the unlikely event of a burst tank, only the stored water within the cooling tank would be released.

Wirsbo PEX Tubing

In 1968, Dr. Thomas Engel invented a process for producing chemically cross-linked polyethylene (PEX) tubing. Considered impossible by many heating industry experts, Wirsbo Co. used Engel's technology to develop a practical manufacturing process for PEX tubing. The cross-linked tubing was introduced to the European floor heating market in 1972 and potable water market in 1973.PEX tubing solved a number of problems that occurred with metal pipes and some other types of plastic tubing. PEX will not corrode or erode, and is immune to the many problems associated with poor water quality that can damage metal pipes. Wirsbo tubing also has a high polymer oxygen diffusion barrier.

Wirsbo-PEX was introduced to the U.S. plumbing market in 1985 by Tomas Lenman, who was a leading member of the engineering team that developed the product in the early 1970s. Today, PEX tubing products are used for floor heating and other heating applications.

Powers' Pressure Balancing Initiatives

In 1964, the Powers Regulator Co., now known as Powers, patented and formally introduced its HydroguardT 410 Pressure Balancing Valve, which protected bathers from steamy blasts or icy bursts by keeping water pressure equalized to the tub or shower.The 410 utilized a unique diaphragm-actuated pressure equalizing chamber to sense and correct any change in the water supply. Failure of the cold water supply shut off hot water delivery to protect the bather.

Rugged construction made the valve well-suited for high-use shower applications in hotels, apartment buildings and schools. Powers advertised the Series 410 as a great way to “shower a welcome” on hotel and motel guests - and keep apartment tenants singing as they soap up!

The concept of controlling water temperature through pressure control dates back to 1887, when company founder William Penn Powers equipped his new three-story heating/plumbing business building with Wisconsin's first central water heating plant.

To eliminate boil-over, he developed a process of controlling the system based on the relative boiling points of water under different pressures. He achieved it via a closed-end, water-filled pipe in the boiler, the other end of which was attached to a diaphragm that controlled a damper.

Slant/Fin's Heat Exchange Fins & Assembly

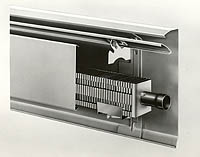

Patented in 1959, this high performance heating element featured double bent, lighter weight fins with interlocking tongue and groove collars.Prior to this invention, finned tube radiation frequently got distorted by handling during installation with a consequent reduction in heating output. Making the individual fins thicker and stiffer helped resist distortion, but also made the radiation clumsier to handle and thereby led to rough treatment. Heavy fins also had sharp or rough edges due to their manufacturing process, presenting a hazard to the installer. Still another drawback was the “reed” effect, a vibration resulting from temperature changes.

The heat exchange fin concept eliminated these drawbacks via an interlocking and fin-touch-fin design. When assembled, these fins supported one another for added strength. Accordingly, the individual fins could be made of lighter-weight material without sacrificing durability.

A result was greater heat transfer, enhanced by the flue effect introduced by the side engagement of the fins in the assembly. The lighter-weight fin material also made for quicker space heating. The fins were devoid of corners and edges and thus less likely to cause injury. Their interlocking arrangements enabled them to maintain constant contact, which eliminated the “reed” effect. <<