One of the most significant “revolutions” in plumbing design in recent years has been the development of product and building designs that take into consideration the special needs of disabled persons. (As a point of clarification, the word “disabled,” as it applies to such plumbing considerations, refers specifically to persons confined to wheelchairs.) The widely accepted term for such products today is “ADA,” standing for the “Americans with Disabilities Act” that triggered many of the regulations in this regard.

Before we proceed any further, let's clarify one other matter. Plumbing for disabled persons is not just a matter of providing specially designed plumbing products. Nor is it simply a case of laying out facilities so such users can maneuver wheelchairs to get at the fixtures more easily. In fact, it involves a varied combination of both considerations.

As an example, most public facilities don't present any particular problem in permitting a person in a wheelchair to approach a regular water cooler; it's just that the design and height of that fixture are inconvenient when the person gets there. This means that a specially designed product model is required. On the other hand, a handicapped person doesn't require a toilet that is any different in basic construction and function than any other; but the person does need that fixture located a bit higher on the wall, and does need a stall and door arrangement that will permit him to get to, and transfer onto, that toilet.

In other words, the meeting of these needs is not simply a matter of “offering a full line of plumbing products for the handicapped.” They can only be fully met through consideration of a combination of fixture, accessory, and layout questions. Though this is primarily a product-oriented series, these subjects are so closely interrelated that we'll be touching on each aspect here.

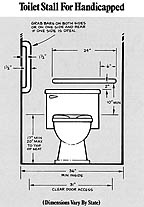

Toilet Stalls:

While there is no uniform standard across the country covering such matters, most codes call for a minimum doorway clearance of approximately 32 inches, and most partition manufacturers today offer doors that meet this criteria. Another requirement for such toilet stalls is the installation of grab bars to support the individual in transferring from the wheelchair to the fixture. Grab bars are typically made of stainless steel tubing, securely anchored to the wall and/or partition. Such arrangements are often oriented both horizontally and vertically, with at least one such bar on each of two walls adjacent to the toilet.Toilet Fixtures:

Toilets for the disabled are usually specified with a seat height in the range of 16 to 19 inches from the floor. To accomplish this, the toilet itself can simply be a standard wall-hung model mounted higher on the wall (nothing different about the toilet, just its positioning). When floor-mounted toilets are used, this does involve a special model in order to provide the required height.

While it might be assumed that toilet seats with integral supporting arms might be just the ticket for such installations, these really get in the way when proper wall-mounted grab bars are provided. Toilet seats with arms are more typically used in residential and other installations in which the user is basically mobile, but needs minor assistance in sitting and getting up again.

Lavatories:

The dimensional specifications called out by ADA require a relatively shallow fixture top to bottom (positioning the fixture 34 inches above the finished floor, with a clearance of at least 29 inches above the finished floor to the bottom of the apron).

In terms of the faucets, ADA dictates: “Controls and operating mechanisms shall be operable with one hand and shall not require tight grasping, pinching, or twisting of the wrist. The force required to activate controls shall be no greater than five pounds.” These requirements are met on manual faucets with lever handles (in the case of both two-handle or single-control types). Obviously, the hands-free capabilities of electronic faucets are a good solution here.

Showers:

The most thorough planning of all is required in the case of shower equipment. Things that most of us take for granted - such as maneuvering on slippery surfaces and responding quickly to sudden temperature changes - are critical considerations for the disabled. (Consider, too, that this is the only way many handicapped persons can bathe. Maneuvering in and out of a tub unassisted is often not an option.)First of all, since the disabled person in mind here has little or no use of his or her legs, there must be a seat in the shower stall. This should preferably be a fold-down type, securely anchored to the wall or partition, and located to facilitate transfer from a wheelchair. Here again, grab bars are a must.

From here, there is no call for specially designed fittings (except for the activation requirements, the same as on lavatory faucets). But there is an important consideration involving the proper selection and placement in the stall. As an example, a thermostatic shower valve will not only protect against sudden changes in temperature output, but require less “maintenance adjustments” of the controls during the time in the shower. And since the user in this case is unable to readily position himself where the water is spraying from a conventional showerhead, a hand-held personal shower is a must. (If both types of shower are included, this means that an in-wall diverter valve must be installed.)

Valve controls, the bracket for the personal shower, and the soap dish or soap dispenser must all be positioned at a reachable level.

Drinking Fountains And Water Coolers:

The design of water coolers has undergone evolving changes over the years to meet ADA requirements, as well. Conventional floor models are too high for easy access from a seated position. While a wall-hung model could simply be mounted at a lower position, this is still not adequate from the standpoint of needed under-clearance. As a result, a specific ADA category of drinking fountain and water cooler is available to meet this need. Basically, this is a wall-mounted design that projects a shallow basin further forward than normal to allow leg clearance below. In the case of water coolers, the bulk of the housing containing the refrigeration package mounts to the wall, with this shallow basin extending further forward. This is more easily done with a drinking fountain, since there are no refrigeration components to contain to the rear. As in the case of other fixtures, there are specific dimensions required for such models, as well as specifications for maximum operating force to turn on the water.Side Bar

The College of Product Knowledge ran in SUPPLY HOUSE TIMES for three years and resulted in a reprint manual that sold for many years to follow, totaling thousands of copies. It became something of an industry classic. Much of the original training material is still applicable to the products sold today - but there is also much in the wholesalers' product mix that is new since then. The purpose of this updated series is to look at what has come along since the first edition.

The CD version of College of Product Knowledge is now available. For information, visit www.supplyht.com or contact Candace Roulo at 248-244-1275, or rouloc@bnpmedia.com.